The Wax Flamingos is a project that two of my classmates and I developed during the behavioral fabrication seminar at ITECH. The goal of this work was to design a cyber-physical system. We drew our inspiration from the simple craft of candle making, where one repeatedly dips a piece of wick until a candle has formed around it. We took this inspiration and designed a fabrication method around it by developing a system feedback that controls the angle at which the object is dipped into the wax. The process is meant to be deployed by a robotic arm, for which everything has been developed, including the end effector and the robot tool paths. Nonetheless, due to unforeseen damage to the manipulator arm that was supposed to be available, the actual deployment still awaits despite everything being ready.

Read More

The Wax Flamingos is a project that two of my classmates and I developed during the behavioral fabrication seminar at ITECH. The goal of this work was to design a cyber-physical system. We drew our inspiration from the simple craft of candle making, where one repeatedly dips a piece of wick until a candle has formed around it. We took this inspiration and designed a fabrication method around it by developing a system feedback that controls the angle at which the object is dipped into the wax. The process is meant to be deployed by a robotic arm, for which everything has been developed, including the end effector and the robot tool paths. Nonetheless, due to unforeseen damage to the manipulator arm that was supposed to be available, the actual deployment still awaits despite everything being ready.

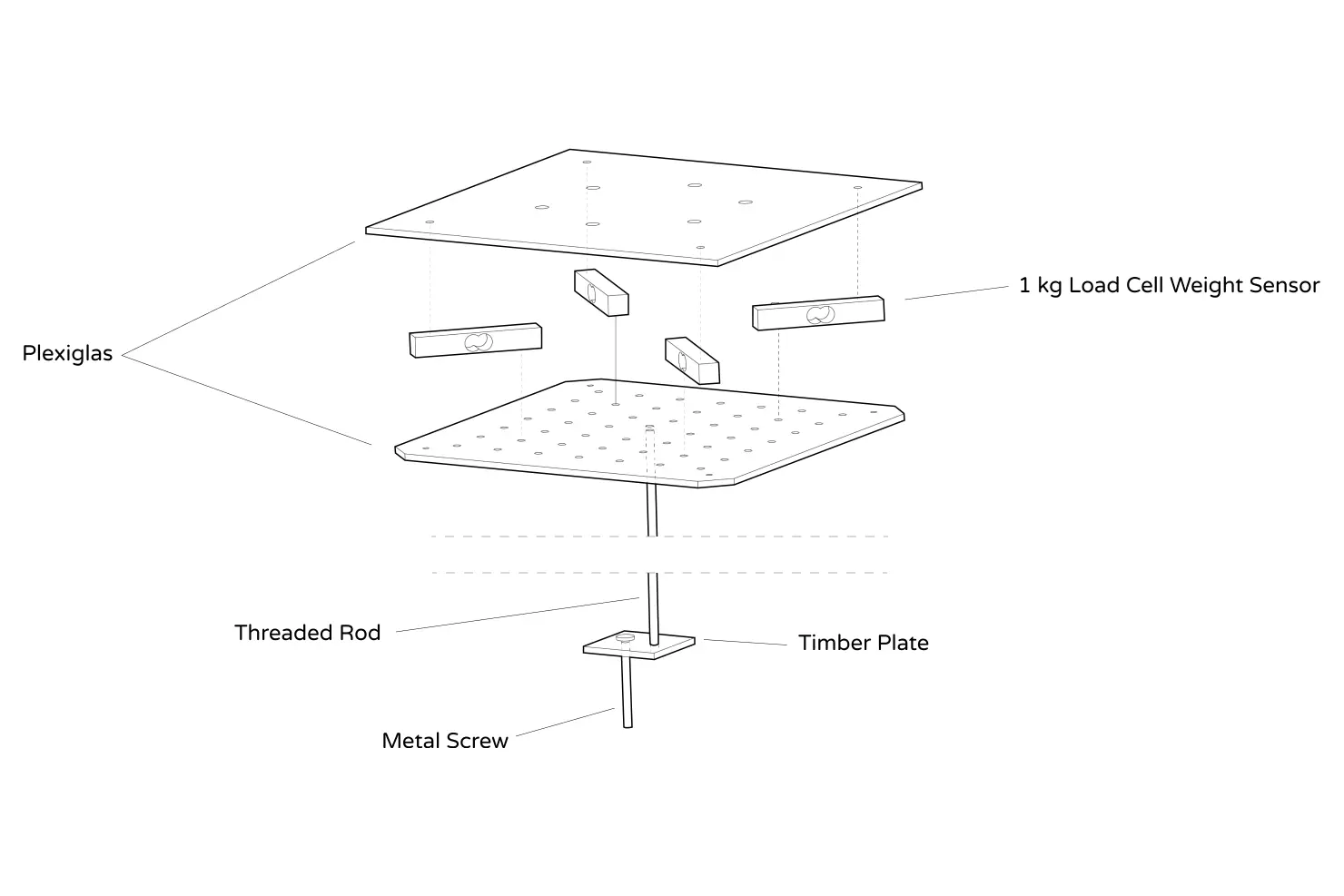

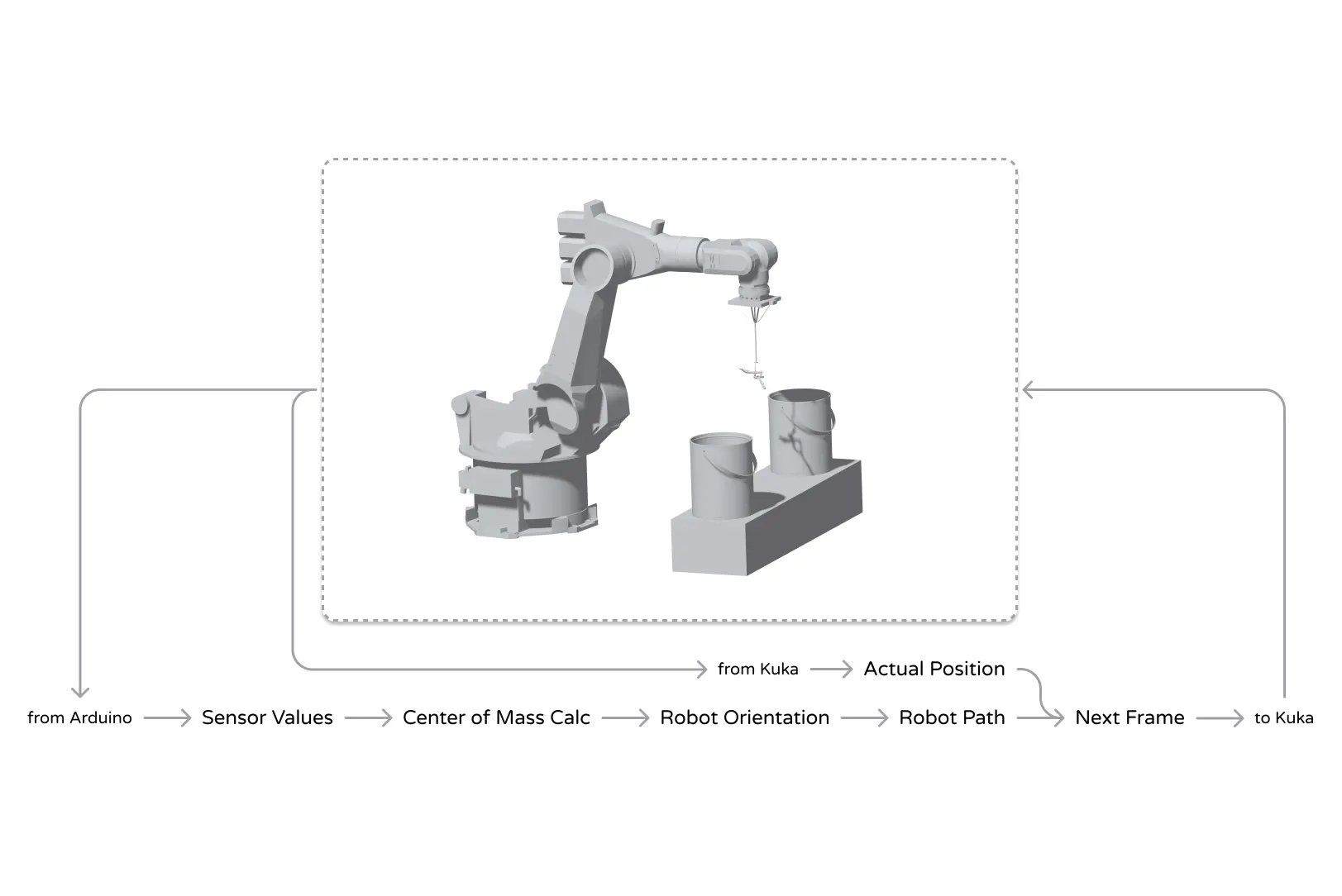

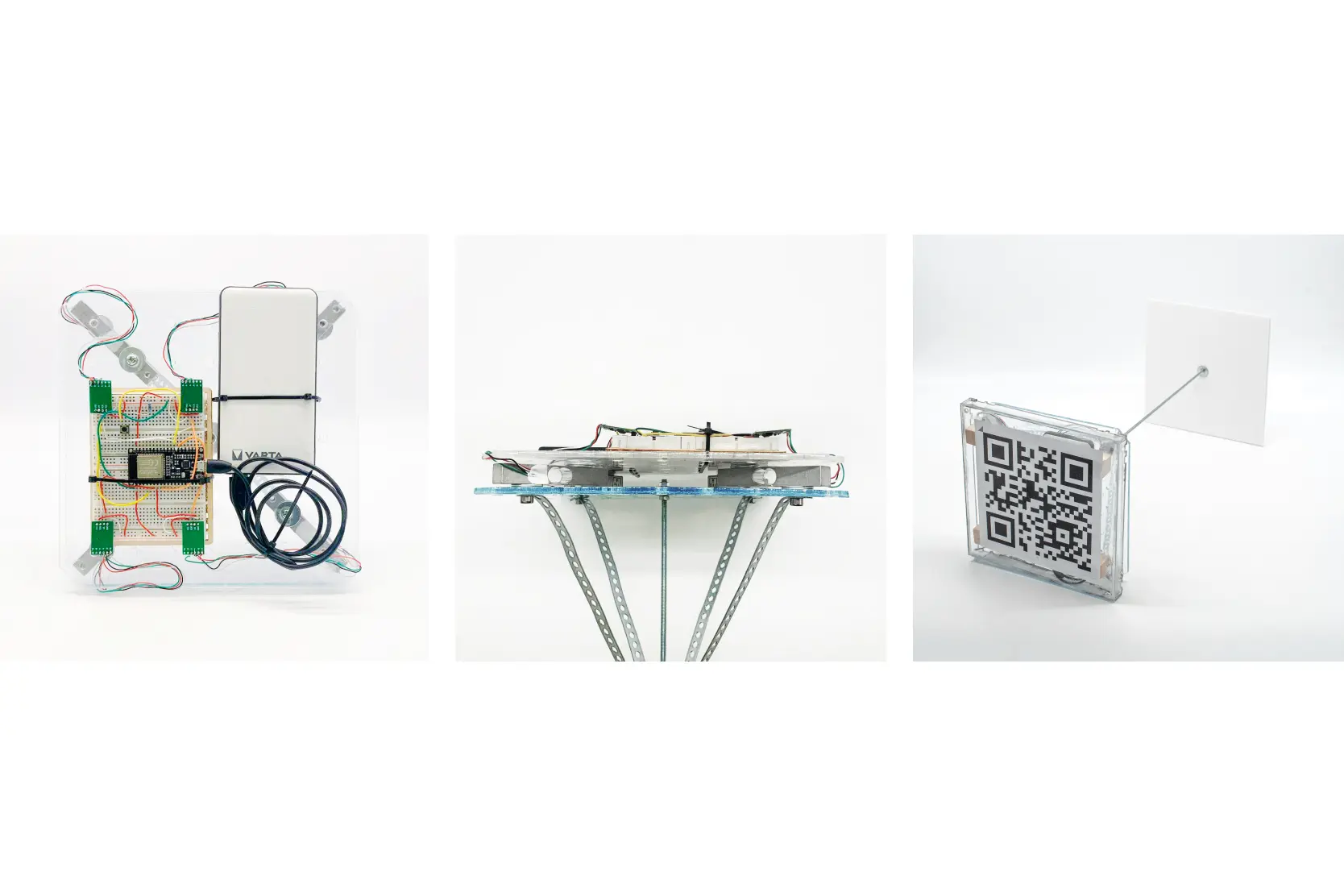

At the heart of this process is a robotic arm equipped with a custom-designed end effector. This end effector holds the object being manipulated and incorporates an array of digital load cell weight sensors. These sensors continuously measure the object's center of gravity, feeding real-time data into a Grasshopper script that guides the robotic arm's movements.

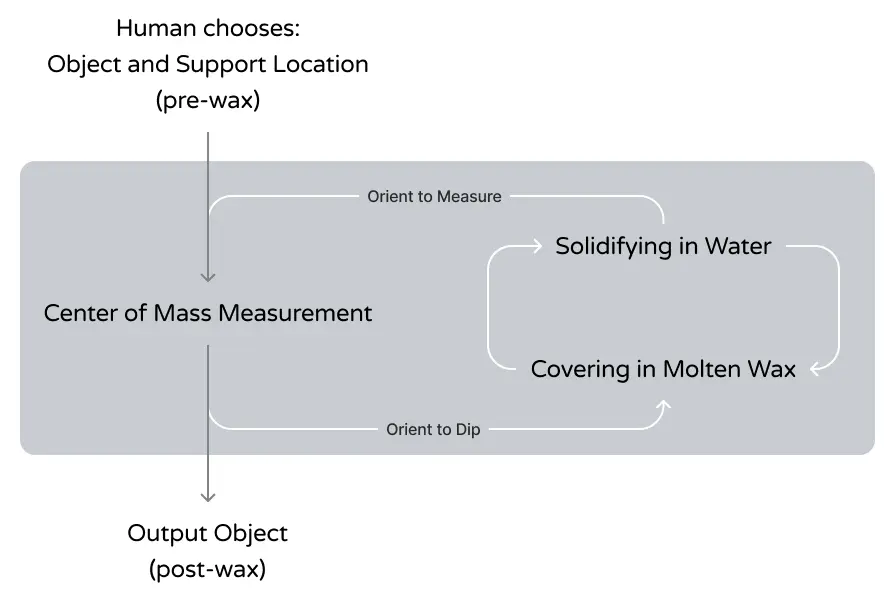

The fabrication begins with preparing the wax, which is melted using a water bath method. In this case, the object is a branch repeatedly dipped into the molten wax and cooled, allowing the wax to accumulate on its surface. Unlike traditional candle making, where the wax deposition is determined mainly by gravity, this cyber-physical system leverages the robotic arm's precision to direct the wax flow strategically.

The system can achieve a highly targeted wax distribution by carefully controlling the angles at which the object is dipped and cooled. This level of control allows for the creation of complex, organic forms that would be difficult to replicate through manual techniques. Moreover, continuously monitoring the object's center of gravity and adjusting the robotic arm's movements accordingly, the system can iteratively refine the wax deposition until the desired balance point is achieved.

The result of this novel fabrication process produces an interesting and aesthetically pleasing artifact: a branch delicately balanced on a metal screw. This outcome is a testament to the power of integrating sensory data and robotic control to manipulate traditionally unpredictable materials. By embracing the indeterminate nature of wax and harnessing the precision of digital fabrication, the project has hinted at new possibilities for creating complex, adaptive forms that blur the boundaries between the natural and the artificial.

Read Less

Stuttgart, Germany

2024

ITECH, University of Stuttgart

In collaboration with Otto Lindstam & Samuel Losi